How To Solder Copper And Aluminum . The first section of this post touches on the basics of soldering to achieve proper wetting, which does not change regardless of soldering to aluminum or copper. — before attempting to join copper and aluminium wires, you must make sure you have all of the necessary tools. aluminum reacts very quickly with oxidizers in the air. how to solder copper to aluminum at 350°f with super alloy 1 and a propane torch. It immediately develops a passive layer of aluminum oxide surrounding the pure metal, making it difficult to solder than copper. — a typical way to make a reliable electrical connection to aluminum is to use a screw and a wire, but [ted] shows that it can also be done with the help of an abrasive and mineral oil. — the most common method of joining copper and aluminium is by soldering or brazing.

from www.youtube.com

how to solder copper to aluminum at 350°f with super alloy 1 and a propane torch. It immediately develops a passive layer of aluminum oxide surrounding the pure metal, making it difficult to solder than copper. — a typical way to make a reliable electrical connection to aluminum is to use a screw and a wire, but [ted] shows that it can also be done with the help of an abrasive and mineral oil. The first section of this post touches on the basics of soldering to achieve proper wetting, which does not change regardless of soldering to aluminum or copper. aluminum reacts very quickly with oxidizers in the air. — before attempting to join copper and aluminium wires, you must make sure you have all of the necessary tools. — the most common method of joining copper and aluminium is by soldering or brazing.

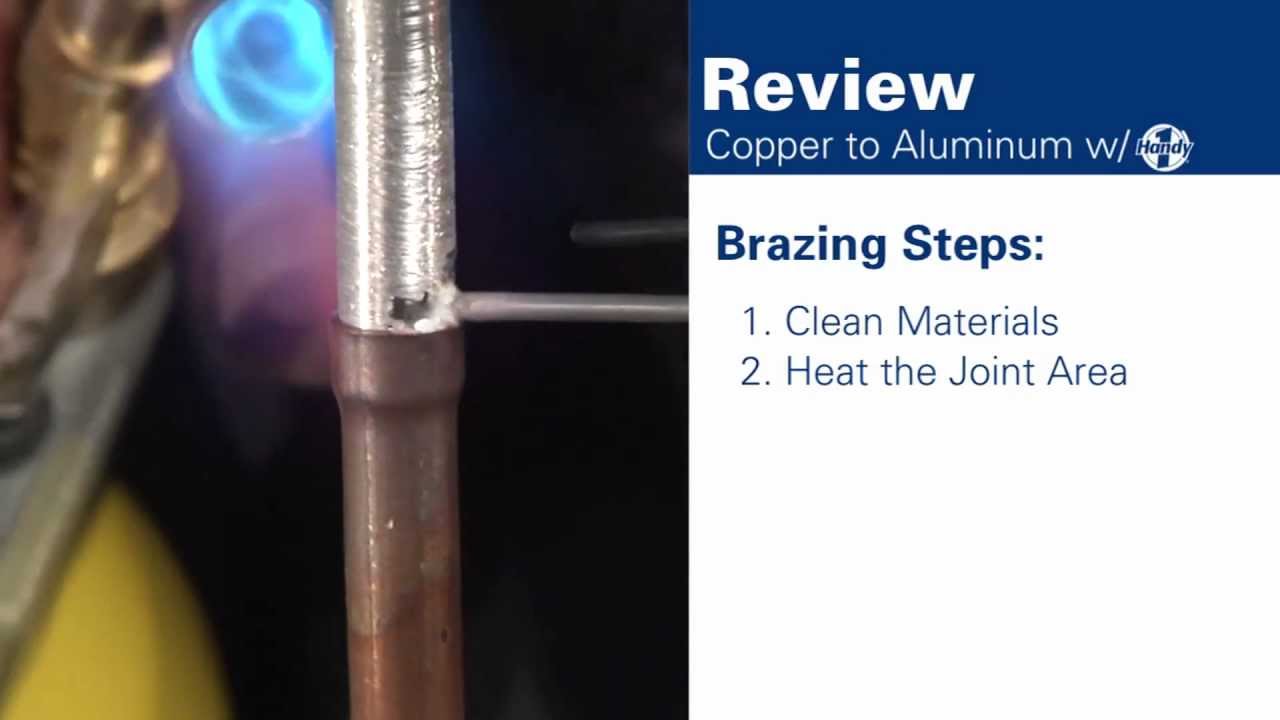

How to Braze Aluminum to Copper YouTube

How To Solder Copper And Aluminum — a typical way to make a reliable electrical connection to aluminum is to use a screw and a wire, but [ted] shows that it can also be done with the help of an abrasive and mineral oil. — before attempting to join copper and aluminium wires, you must make sure you have all of the necessary tools. aluminum reacts very quickly with oxidizers in the air. how to solder copper to aluminum at 350°f with super alloy 1 and a propane torch. It immediately develops a passive layer of aluminum oxide surrounding the pure metal, making it difficult to solder than copper. The first section of this post touches on the basics of soldering to achieve proper wetting, which does not change regardless of soldering to aluminum or copper. — the most common method of joining copper and aluminium is by soldering or brazing. — a typical way to make a reliable electrical connection to aluminum is to use a screw and a wire, but [ted] shows that it can also be done with the help of an abrasive and mineral oil.

From www.youtube.com

How to Braze Aluminum to Copper YouTube How To Solder Copper And Aluminum — a typical way to make a reliable electrical connection to aluminum is to use a screw and a wire, but [ted] shows that it can also be done with the help of an abrasive and mineral oil. — before attempting to join copper and aluminium wires, you must make sure you have all of the necessary tools.. How To Solder Copper And Aluminum.

From www.youtube.com

How to Solder copper wire to aluminum foil. YouTube How To Solder Copper And Aluminum how to solder copper to aluminum at 350°f with super alloy 1 and a propane torch. — a typical way to make a reliable electrical connection to aluminum is to use a screw and a wire, but [ted] shows that it can also be done with the help of an abrasive and mineral oil. — the most. How To Solder Copper And Aluminum.

From blog.thepipingmart.com

How to Solder Aluminum to Copper A Complete Guide How To Solder Copper And Aluminum — before attempting to join copper and aluminium wires, you must make sure you have all of the necessary tools. — a typical way to make a reliable electrical connection to aluminum is to use a screw and a wire, but [ted] shows that it can also be done with the help of an abrasive and mineral oil.. How To Solder Copper And Aluminum.

From www.youtube.com

AlumSolder Alu Flux use solder and soldering iron to join aluminium How To Solder Copper And Aluminum It immediately develops a passive layer of aluminum oxide surrounding the pure metal, making it difficult to solder than copper. The first section of this post touches on the basics of soldering to achieve proper wetting, which does not change regardless of soldering to aluminum or copper. — a typical way to make a reliable electrical connection to aluminum. How To Solder Copper And Aluminum.

From www.youtube.com

HVAC Soldering Basics YouTube How To Solder Copper And Aluminum It immediately develops a passive layer of aluminum oxide surrounding the pure metal, making it difficult to solder than copper. The first section of this post touches on the basics of soldering to achieve proper wetting, which does not change regardless of soldering to aluminum or copper. how to solder copper to aluminum at 350°f with super alloy 1. How To Solder Copper And Aluminum.

From www.pinterest.com

How to solder copper pipe Welding rods, Bernzomatic, Soldering copper How To Solder Copper And Aluminum — a typical way to make a reliable electrical connection to aluminum is to use a screw and a wire, but [ted] shows that it can also be done with the help of an abrasive and mineral oil. It immediately develops a passive layer of aluminum oxide surrounding the pure metal, making it difficult to solder than copper. The. How To Solder Copper And Aluminum.

From www.instructables.com

How to CORRECTLY Solder a Copper Pipe 6 Steps (with Pictures) How To Solder Copper And Aluminum It immediately develops a passive layer of aluminum oxide surrounding the pure metal, making it difficult to solder than copper. aluminum reacts very quickly with oxidizers in the air. — before attempting to join copper and aluminium wires, you must make sure you have all of the necessary tools. The first section of this post touches on the. How To Solder Copper And Aluminum.

From www.instructables.com

Brass and Copper Soldering 12 Steps (with Pictures) Instructables How To Solder Copper And Aluminum — a typical way to make a reliable electrical connection to aluminum is to use a screw and a wire, but [ted] shows that it can also be done with the help of an abrasive and mineral oil. — before attempting to join copper and aluminium wires, you must make sure you have all of the necessary tools.. How To Solder Copper And Aluminum.

From hackaday.com

How To Solder To Aluminum, Easily Hackaday How To Solder Copper And Aluminum — the most common method of joining copper and aluminium is by soldering or brazing. It immediately develops a passive layer of aluminum oxide surrounding the pure metal, making it difficult to solder than copper. — a typical way to make a reliable electrical connection to aluminum is to use a screw and a wire, but [ted] shows. How To Solder Copper And Aluminum.

From exoceylni.blob.core.windows.net

Aluminum Copper Brazing Rod at Fred Becerra blog How To Solder Copper And Aluminum how to solder copper to aluminum at 350°f with super alloy 1 and a propane torch. — before attempting to join copper and aluminium wires, you must make sure you have all of the necessary tools. — the most common method of joining copper and aluminium is by soldering or brazing. It immediately develops a passive layer. How To Solder Copper And Aluminum.

From www.museoinclusivo.com

Can You Solder Aluminum to Copper? A StepbyStep Guide Aluminum How To Solder Copper And Aluminum — the most common method of joining copper and aluminium is by soldering or brazing. — before attempting to join copper and aluminium wires, you must make sure you have all of the necessary tools. It immediately develops a passive layer of aluminum oxide surrounding the pure metal, making it difficult to solder than copper. aluminum reacts. How To Solder Copper And Aluminum.

From www.youtube.com

How to Solder Copper Pipe The CORRECT Way GOT2LEARN YouTube How To Solder Copper And Aluminum It immediately develops a passive layer of aluminum oxide surrounding the pure metal, making it difficult to solder than copper. — the most common method of joining copper and aluminium is by soldering or brazing. aluminum reacts very quickly with oxidizers in the air. how to solder copper to aluminum at 350°f with super alloy 1 and. How To Solder Copper And Aluminum.

From solderingironguide.com

How to Solder Aluminum Guide For Beginners How To Solder Copper And Aluminum how to solder copper to aluminum at 350°f with super alloy 1 and a propane torch. It immediately develops a passive layer of aluminum oxide surrounding the pure metal, making it difficult to solder than copper. — a typical way to make a reliable electrical connection to aluminum is to use a screw and a wire, but [ted]. How To Solder Copper And Aluminum.

From www.youtube.com

Solder Aluminum To Copper "How To" YouTube How To Solder Copper And Aluminum — before attempting to join copper and aluminium wires, you must make sure you have all of the necessary tools. It immediately develops a passive layer of aluminum oxide surrounding the pure metal, making it difficult to solder than copper. aluminum reacts very quickly with oxidizers in the air. how to solder copper to aluminum at 350°f. How To Solder Copper And Aluminum.

From www.youtube.com

Basic Soldering YouTube How To Solder Copper And Aluminum — the most common method of joining copper and aluminium is by soldering or brazing. how to solder copper to aluminum at 350°f with super alloy 1 and a propane torch. The first section of this post touches on the basics of soldering to achieve proper wetting, which does not change regardless of soldering to aluminum or copper.. How To Solder Copper And Aluminum.

From dxosxutlx.blob.core.windows.net

Solder To Weld at Lorraine Dowdy blog How To Solder Copper And Aluminum — before attempting to join copper and aluminium wires, you must make sure you have all of the necessary tools. It immediately develops a passive layer of aluminum oxide surrounding the pure metal, making it difficult to solder than copper. aluminum reacts very quickly with oxidizers in the air. — a typical way to make a reliable. How To Solder Copper And Aluminum.

From blog.thepipingmart.com

How to Solder Aluminium Tubing A StepbyStep Guide How To Solder Copper And Aluminum — the most common method of joining copper and aluminium is by soldering or brazing. how to solder copper to aluminum at 350°f with super alloy 1 and a propane torch. — before attempting to join copper and aluminium wires, you must make sure you have all of the necessary tools. The first section of this post. How To Solder Copper And Aluminum.

From www.youtube.com

Copper to Aluminum Brazing/soldering YouTube How To Solder Copper And Aluminum how to solder copper to aluminum at 350°f with super alloy 1 and a propane torch. — the most common method of joining copper and aluminium is by soldering or brazing. — a typical way to make a reliable electrical connection to aluminum is to use a screw and a wire, but [ted] shows that it can. How To Solder Copper And Aluminum.